Prefinish Options

- We carefully disassemble the door system. This helps to get behind the hinges, at all the nook & crannies, all 6 sides of the door (including the top and bottom).

- We caulk and glaze all glass areas to help prevent any water intrusion.

- We tape off all windows and threshold to protect from over-spray finish.

- Wood filler is applied where needed to help attain smoothness.

- If there are any imperfections in the wood itself, we remove them with a steaming process.

- Bare wood sanding by hand is done.

- Stain with UV protection is applied by spray gun. This process soaks into wood to give added sun protection.

- Generous block sanding is applied to all six sides of the door.

- Inspect the door for any imperfections from the stain process and if necessary, apply touch up stain.

- Apply the first coat of sanding sealer to all six sides of the door. Block sand to smooth raised grains.

- Apply a second sealer coating to all sides.

- Scuff sand to smooth out sealer coating.

- Apply touch up sealer coating.

- Repeat steps 11 thru 13, if necessary to ensure that door is completely sealed.

- Apply UV Top Coats. (low sheen or satin finish)

- 24 to 48 hour curing.

- Caulk exterior glass, Caulk where jamb legs meet the threshold, Remove all taping.

- Reassemble the door system. Install Door Sweep, Astragal boot, weather-stripping.

- Prepare the door system for shipping, including shipping protectors and shrink wrapping.

- Door system moves to shipping department for complete protective crating.

Our Standard Finishing costs are for the above 20 steps. Distressing: Exterior and Interior Wood Doors. Light, Medium or Heavy Distressing. Antiqued Finishes: Lightly Antiqued to Heavily Antiqued.

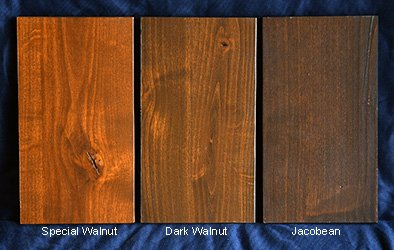

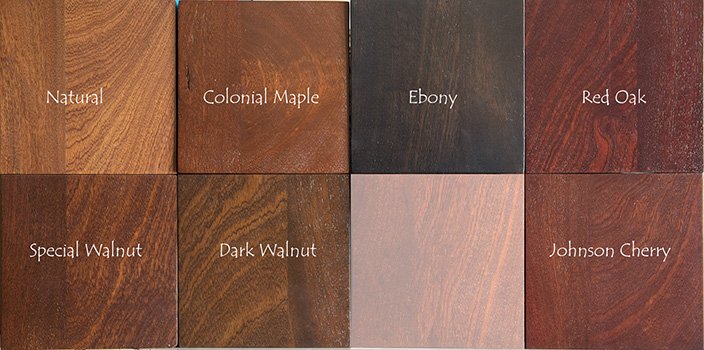

Exterior Knotty Alder Stain Samples

Disclaimer: the color samples may appear differently from display to display. We will not be held responsible for color matching issues based on this chart alone.

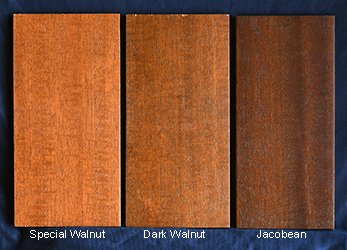

Brazilian Mahogany Stain Samples

Disclaimer: the color samples may appear differently from display to display. We will not be held responsible for color matching issues based on this chart alone.

White Oak Interior Doors Stain

Disclaimer: the color samples may appear differently from display to display. We will not be held responsible for color matching issues based on this chart alone.

Knotty Alder Interior Doors Stain

Disclaimer: the color samples may appear differently from display to display. We will not be held responsible for color matching issues based on this chart alone.

Mahogany Interior Doors Stain

Disclaimer: the color samples may appear differently from display to display. We will not be held responsible for color matching issues based on this chart alone.

Poplar Interior Doors Stain Samples

Disclaimer: the color samples may appear differently from display to display. We will not be held responsible for color matching issues based on this chart alone.

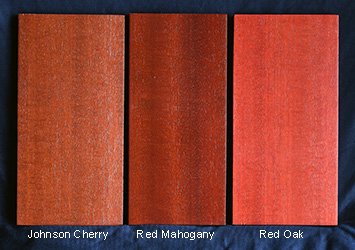

Red Oak Interior Doors Stain Samples

Disclaimer: the color samples may appear differently from display to display. We will not be held responsible for color matching issues based on this chart alone.

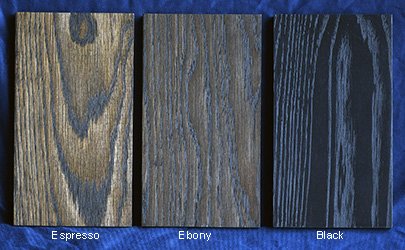

Cedar Garage Door Samples

Examples of UV stain colors on Alaskan Red Cedar overhead garage doors. exterior-grade UV Stains and Sealers

Disclaimer: the color samples may appear differently from display to display. We will not be held responsible for color matching issues based on this chart alone.

Sapele African Mahogany Wood Stain

Examples of UV stain colors on Alaskan Red Cedar overhead garage doors. exterior-grade UV Stains and Sealers

Disclaimer: the color samples may appear differently from display to display. We will not be held responsible for color matching issues based on this chart alone.

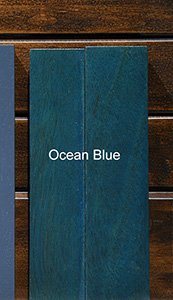

Blue Color Samples

Examples of Blue stain colors. Exterior-Grade UV Sealers

Disclaimer: the color samples may appear differently from display to display. We will not be held responsible for color matching issues based on this chart alone.